Driving Sustainable Development

Pioneering sustainability in every print

At Pinpops®, we operate under a proactive environmental policy, constantly refining our processes and products to align with sustainable development goals. Our objective is to build a responsible future and ensure a cleaner environment for the generations to follow.

Our 1,500 m2 production facility in Helsinki has undergone significant energy-efficiency upgrades, including a complete transition to modern LED lighting. To manage the cold Nordic winters sustainably, we utilize district heating. These modern, energy-efficient premises are key to reducing our overall carbon footprint.

The facility features floor-to-ceiling windows that allow us to maximize natural daylight, significantly reducing our reliance on artificial lighting. In addition to lowering energy consumption, this abundance of natural light creates a healthier and more inspiring workspace for our production team.

Large windows throughout our production facility maximize the use of natural light

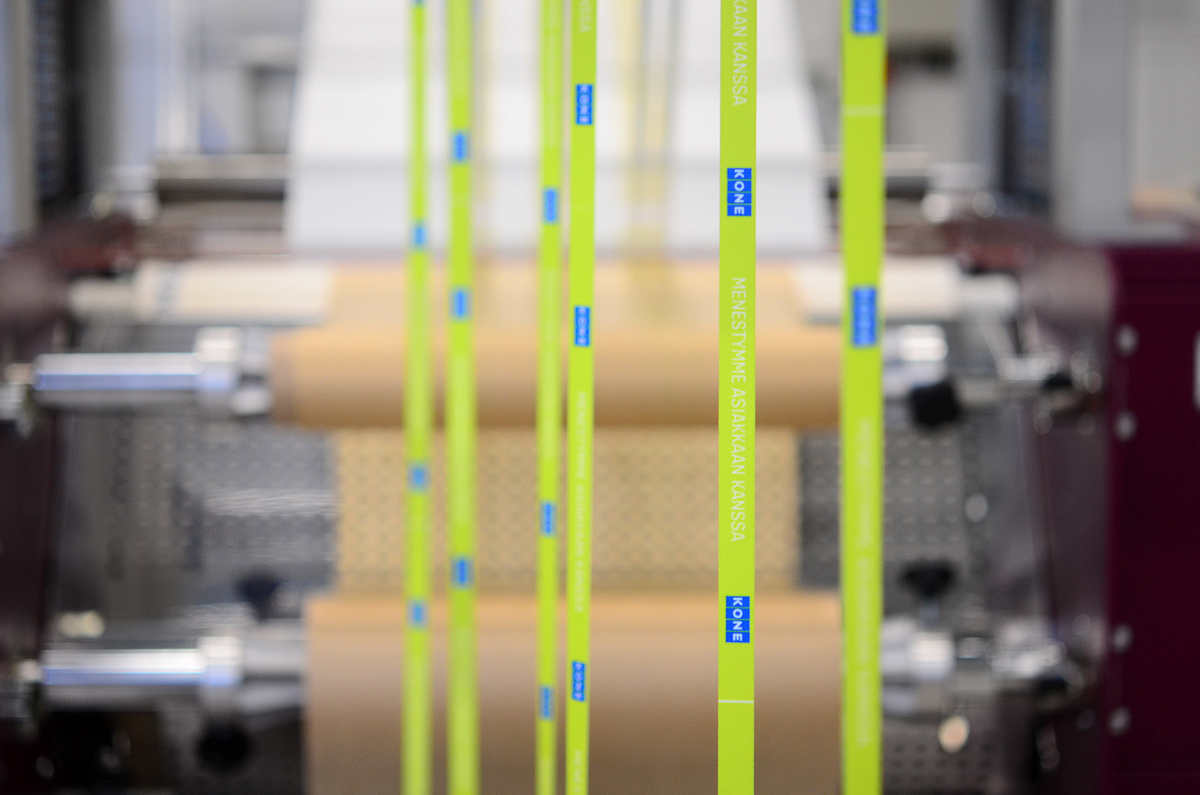

Our state-of-the-art printing presses are designed for high energy efficiency and minimal material waste. When upgrading our machinery, we prioritize technologies that reduce environmental impact and eliminate harmful elements from the production cycle.

A major part of our production, sublimation printing, utilizes water-based, Oeko-Tex® certified inks. This international safety standard ensures that our products are non-toxic and free from harmful substances—a critical factor for items worn close to the skin. With over one million lanyards sold annually across Europe and the US, our commitment to certified materials and rPET recycled plastics creates a significant positive impact at scale.

Oeko-Tex® certified non-toxic inks support safe and responsible production

We are constantly sourcing more responsibly produced materials and recycled components to minimize our environmental footprint. A key initiative is our transition from standard polyester lanyards to rPET models made from recycled plastic bottles. Scale matters: selling over a million lanyards annually across Europe means this shift has a significant environmental impact.

Furthermore, we facilitate the recycling of our own products. We accept used badges and disposable event ID items, ensuring they are forwarded to the correct material recycling facilities to close the production loop.